From specialist medical devices and advanced audio equipment to complex traffic management systems and high-tech automotive components, our advanced surface mount technology (SMT) and expert team ensure precision at every stage.

With over 40 years of experience and a steadfast commitment to meticulous quality standards, we provide a complete, end to end service – transforming projects from prototype to volume production with exceptional reliability and speed. Partner with TAL Group to gain a competitive edge through our technical expertise, innovative processes and dedication to customer satisfaction.

Accreditations include:

ISO 9001:2015

Operators IPC-A-610 certified

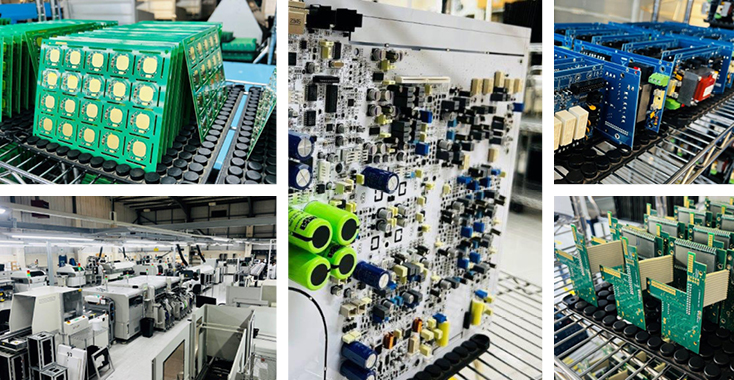

TAL Group delivers precision PCB assembly using advanced HSP/GSM lines capable of placing BGA, TQFP, and PLCC devices with ease. Operating in a fully controlled ESD environment, we handle single- and double-sided PCBs using paste or glue techniques. Predictive software fine tunes the reflow process to optimise yields and ensure reliable joint integrity, supporting up to 40 million component placements per month.

Our skilled operators manage six fully tracked lines for flexible through-hole assembly solutions. From bare board to final assembly, we build each unit with precision and full traceability.

TAL Group offers complete unit or sub assembly services, including chassis and sub unit assembly, full unit assembly, cable and harness integration, functional and ATE testing, product configuration and medium to high volume unit builds.

We provide superior conformal coating using atomised, non-atomised and non-contact application techniques. Advanced offline programming and selective coating processes ensure protection and reliability for every assembly.

Our universal insertion equipment handles both axial and radial through-hole assemblies efficiently. Adjustable tooling plates reduce setup costs; all programming and component sequencing are generated in-house to meet exacting specifications.

We offer a complete range of cable assemblies, looms and harnesses, manufactured using customer drawings, bills of materials (BOMs) or samples. Our experienced team customises the manufacturing process to ensure it is best suited to each loom requirement. By utilising a wide range of production and testing equipment, we deliver a consistently high level of service, ensuring customers receive a quality product exactly when required.